MB-320 : Microsoft Dynamics 365 Supply Chain Management, Manufacturing : Part 04

MB-320 : Microsoft Dynamics 365 Supply Chain Management, Manufacturing : Part 04

-

A company produces rubber hose using Discreet orders accounts for raw material scrap after report as finished through inventory movement journals.

The company has noticed that most of the scrap that is recorded is due to start up that feeds the hose to the finishing process. In addition, the amount of scrap that is recorded is consistent regardless of the amount of hose being produced.

You need to account for material cost during startup.

What should you do?

- Do a case study for the scrap items and enter the average amount of scrap as a separate line items on the Bill of materials.

- Enter the amount of scrap that is consumed as constant scrap in the Bill of materials.

- Enter the amount of scrap that is consumed as variable scrap in the Bill of materials.

- Enter the consumption amount on the line to match the actual amount used.

-

A Discrete manufacturing company produces speakers. The high-end speaker model uses protective rubber strips on the edges.

Approximately five inches of rubber is consistently scrapped in the production process, regardless of production quantity. Workers manually consume the extra material on the picking list or scrap it in an inventory journal.

You need configure the system to automatically account for this scrap on the Bill of materials (BOM).

What should you do?

- Increase the required quantity of the rubber component by five on the BOM

- Set a variable scrap of five percent for the rubber BOM line

- Add an additional BOM line for five inches and set consumption to Variable

- Set a Constant scrap of five on the BOM line for rubber

-

A company implements Dynamics 365 Supply Chain Management.

Due to increased demand and limited space in the work cell area for product L0050, you must subcontract overflow work to another company. You have the following requirements:

– Locate a warehouse at the subcontractor building.

– Support picking and shipping activity tracking.

– Associate costs of transporting materials between the locations in the cost of the finished product.You need to modify the production flow.

Which three actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

- Modify the overflow work activity and assign it to subcontractor

- Create transfer activities and assign them to the subcontractor

- Create a resource and work cell resource group for the subcontractor

- Create a new production flow version

- Modify the overflow work operation and associate it with the subcontractor

-

You are a production manager at a company that has implemented lean manufacturing using Dynamics 365 Supply Chain Management.

You have created a new Kanban rule to replace one that is expiring.

You need to determine the impact to the existing process jobs.

How are the active Kanbans of the expired rule handled?

- The active Kanbans are set to add to the requested period and distribute for the replacement rule time fence.

- The active Kanban handling units are registered as empty and new Kanbans are created.

- The active Kanbans are cancelled.

- The active Kanbans are counted as Kanbans of the replaced rule.

-

A manufacturing plant uses Lean manufacturing. Operators process Kanban consumption manually by using a mobile device.

The production team must use automatic empty registration for some of the event Kanbans. Registration must occur when the last job of a Kanban is completed.

You need to update the Kanban rule to meet this requirement.

What Kanban setting should you update?

- Select to register as empty when the source requirement is registered

- Select to register as empty when handling units are received

- Select to manually register as empty

- Set a fixed Kanban quantity

-

You are the production planner for a manufacturing company.

After running operations scheduling for a production order, the following error message displays:

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q06 041 Navigate to the work calendar and view working times. Validate that there are working days created in the scheduled period.You need to identify the cause of the error.

Which two actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

- Navigate to the work calendar and view working times. Validate that there are working days created in the scheduled period.

- Review the calendar for the resource to determine if it is expired.

- Review the available resources for Operation 10. Navigate to the Resource form and validate whether there is a calendar assigned.

- Review the resource group assigned to Operation 10. Check to see if there is a calendar assigned and if the calendar is expired.

-

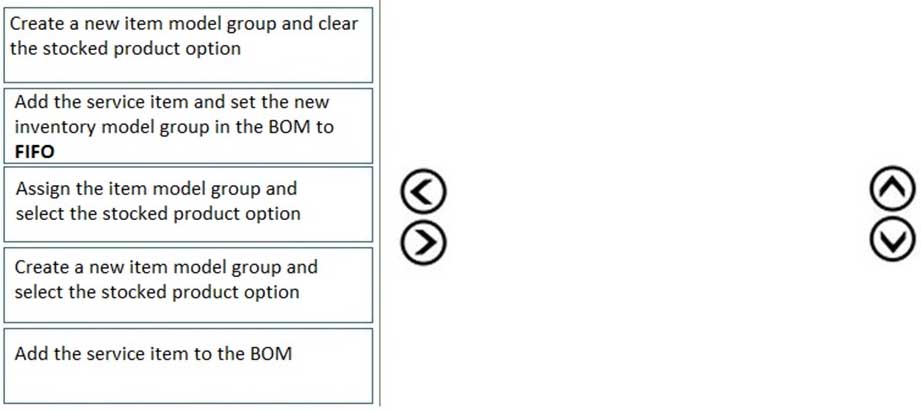

DRAG DROP

A manufacturer sends wiring harnesses to a vendor to be soldered to a connector. You have created the subcontracting process in the bill of materials (BOM) and route to account for the items sent to the vendor.

You create separate subcontracting purchase orders to account for the service. You attempt to add the service item to the BOM. The system generates an error.

You need to set up a new item model group for the service item.

Which three actions should you perform? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q07 042 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q07 042 Answer -

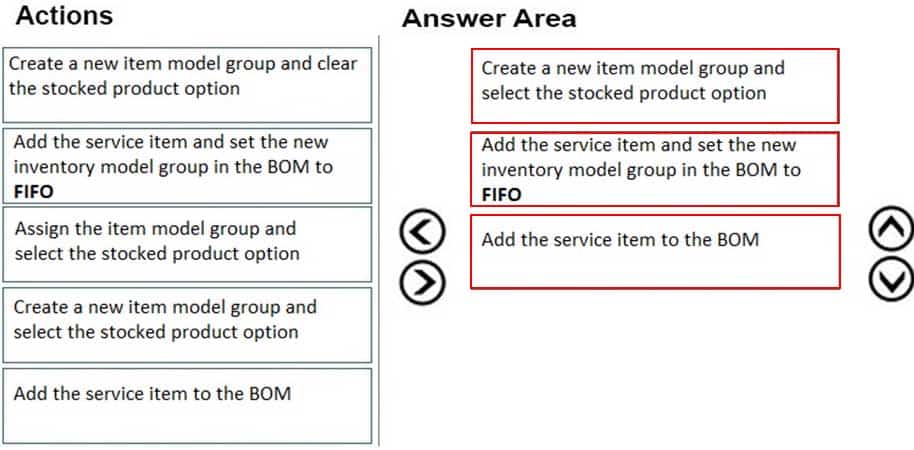

DRAG DROP

A company that uses Lean manufacturing concepts to produce paper plates has redesigned the layout of the warehouse and production floor.

The company’s production flow activities no longer match the tasks of the workers. Employees use paper and manual communication to complete the tasks.

You need to update the production flows to match their current processes by deactivating the obsolete production flows and creating new ones.

Which five actions should you perform in sequence? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q08 043 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q08 043 Answer -

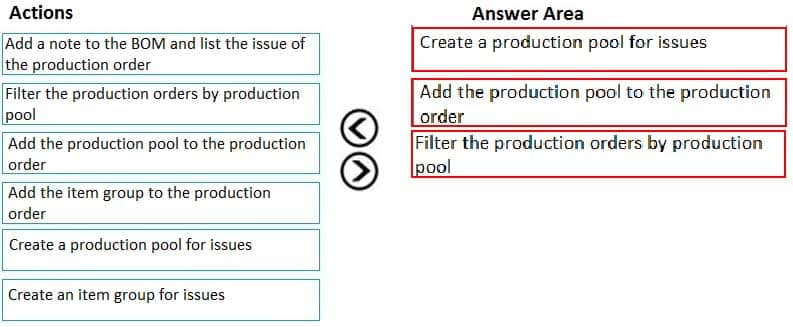

DRAG DROP

A company uses Discreet manufacturing concepts to produce cables. The company’s production scheduler uses internal documents to track issues on in-process production orders.

The production scheduler must group all in-process production orders according to issues. The scheduler must be able to easily determine issues with production orders.

You need to implement a method to easily identify production orders with issues.

Which three actions should you perform in sequence? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q09 044 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q09 044 Answer -

You have a product that can be manufactured on two different production lines in the same warehouse. You create resources and then create individual input locations for the resources. You create two routes. Each route uses different resources.

Materials are staged for consumption in different locations based on the resources being utilized for production.

You need to set up the formula to consume the goods from the correct line-side location.

What should you do?

- Select a warehouse and consumption operation for each line.

- Select resource consumption and the operation for each line.

- Select the plan group and consumption operation for each line.

- Specify a site in the formula header.

-

You are responsible for training the operations staff on production transactions in Dynamics 365 Supply Chain Management. The company uses back flushing for material consumption principles.

You need to train the operators on how to report unintended scrap.

What are two possible ways to achieve this goal? Each correct answer presents a complete solution.

NOTE: Each correct selection is worth one point.

- Report additional time in route card journal

- Post additional materials in a picking list journal

- Report an error quantity at Report as finished

- Report an additional good quantity at Report as finished

-

Note: This question is part of a series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some questions sets might have more than one correct solutions, while others might not have a correct solution.

After you answer a question in this section, you will NOT be able to return to it. As a result, these questions will not appear in the review screen.

A company implements Dynamics 365 Supply Chain Management for their Lean manufacturing environment.

There has been an engineering change to a fixed quantity product that is in production. This change will add an additional processing step as the second step. The existing version must be phased out and replaced by the new version.

You need to ensure that the engineering change takes affect at the end of the month.

Solution:

1.) Edit the existing step number two activity to be the new engineering process

2.) Edit the existing production flow. Set the expiration date due to the end of the month

3.) Edit the existing Kanban rule. Set the expiration date to the end of the month

4.) Activate the production flowDoes the solution meet the goal?

- Yes

- No

-

Note: This question is part of a series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some questions sets might have more than one correct solutions, while others might not have a correct solution.

After you answer a question in this section, you will NOT be able to return to it. As a result, these questions will not appear in the review screen.

A company implements Dynamics 365 Supply Chain Management for their Lean manufacturing environment.

There has been an engineering change to a fixed quantity product that is in production. This change will add an additional processing step as the second step. The existing version must be phased out and replaced by the new version.

You need to ensure that the engineering change takes affect at the end of the month.

Solution:

1.) Create an activity for the new process step and add it to the existing production flow. Set the expiration date to the end of the month

2.) Create a Kanban rule that incorporates the new activity with an effective date of end of the month

3.) Edit the existing Kanban rule. Set the expiration date to the end of the month.

4.) Activate the new production flowDoes the solution meet the goal?

- Yes

- No

-

Note: This question is part of a series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some questions sets might have more than one correct solutions, while others might not have a correct solution.

After you answer a question in this section, you will NOT be able to return to it. As a result, these questions will not appear in the review screen.

A company implements Dynamics 365 Supply Chain Management for their Lean manufacturing environment.

There has been an engineering change to a fixed quantity product that is in production. This change will add an additional processing step as the second step. The existing version must be phased out and replaced by the new version.

You need to ensure that the engineering change takes affect at the end of the month.

Solution:

1.) Add a new version to the existing production flow. Set the expiration date to the end of the month.

2.) Create an activity for the new process step and add it in the proper sequence

3.) Create a Kanban rule that incorporates the new activity. Set the expiration date to the end of the month.

4.) Edit the existing Kanban rule. Set the expiration date to the end of the month. Specify the new Kanban rules as the replacement ruleDoes the solution meet the goal?

- Yes

- No

-

Note: This question is part of a series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some questions sets might have more than one correct solutions, while others might not have a correct solution.

After you answer a question in this section, you will NOT be able to return to it. As a result, these questions will not appear in the review screen.

A manufacturing plant uses Lean process. You plan to outsource a painting operation to a subcontracting vendor. You create a service item named SP-01 to represent the painting service.

You need to create a subcontracting activity for the painting service.

Solution:

1.) Create a purchase agreement for the subcontracting vendor that contains the pricing information for SP-01

2.) Create a vendor resource and a work cell for outsourced painting, then add the resource to the work cell

3.) Create a production flow process activity using the painting work cell and the service item as the picking activity

4.) Create a service term on the activity to tie the purchase agreement to the activityDoes this solution meet the goal?

- Yes

- No

-

Note: This question is part of a series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some questions sets might have more than one correct solutions, while others might not have a correct solution.

After you answer a question in this section, you will NOT be able to return to it. As a result, these questions will not appear in the review screen.

A manufacturing plant uses Lean process. You plan to outsource a painting operation to a subcontracting vendor. You create a service item named SP-01 to represent the painting service.

You need to create a subcontracting activity for the painting service.

Solution:

1.) Create a vendor warehouse for the subcontracting vendor

2.) Create a vendor resource and add it to a new work cell for outsource painting

3.) Create a production flow transfer activity and specify the vendor warehouse as the target warehouseDoes this solution meet the goal?

- Yes

- No

-

Note: This question is part of a series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some questions sets might have more than one correct solutions, while others might not have a correct solution.

After you answer a question in this section, you will NOT be able to return to it. As a result, these questions will not appear in the review screen.

A manufacturing plant uses Lean process. You plan to outsource a painting operation to a subcontracting vendor. You create a service item named SP-01 to represent the painting service.

You need to create a subcontracting activity for the painting service.

Solution:

1.) Create a purchase agreement for the subcontracting vendor and add SP-01 as the painting service

2.) Create a vendor resource then create a work cell for outsourced painting and add the resource to the work cell

3.) Create a production flow process activity for the painting work cell and add the component to be painted as a picking activity

4.) Create a service term to tie the purchase agreement to the activityDoes this solution meet the goal?

- Yes

- No

-

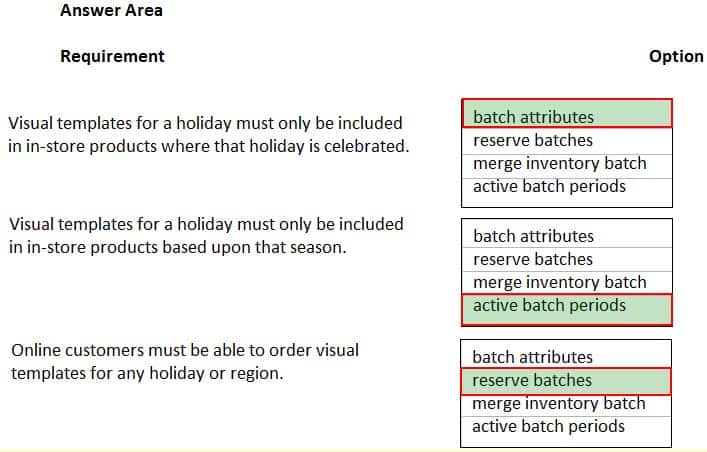

HOTSPOT

A company produces light projection toys for holiday decorations. The company plans to implement Lean manufacturing processes.

Production master data must meet the following requirements:

– Visual templates for a holiday must only be included for in-store products where that holiday is celebrated

– Visual templates for a holiday must only be included for in-store products based upon that season

– Online customers must be able to order visual templates for any holiday or region.You need to implement production master data.

What should you configure? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q18 045 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q18 045 Answer -

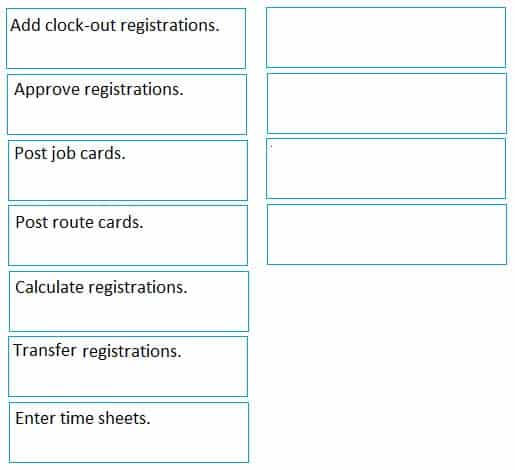

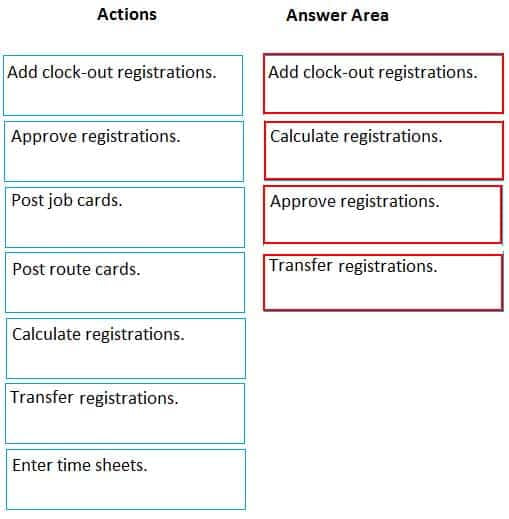

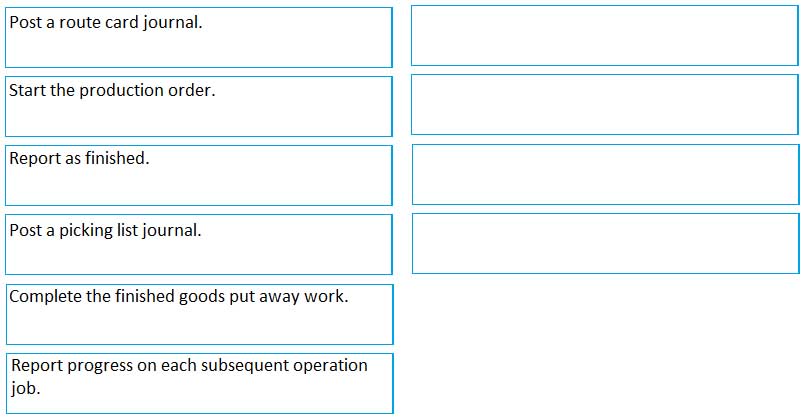

DRAG DROP

A company uses manufacturing execution for processing of production orders. Multiple production orders from last week need to be ended.

You need to process the time registrations to allow the orders to end.

Which four steps should you perform in sequence? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q19 046 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q19 046 Answer -

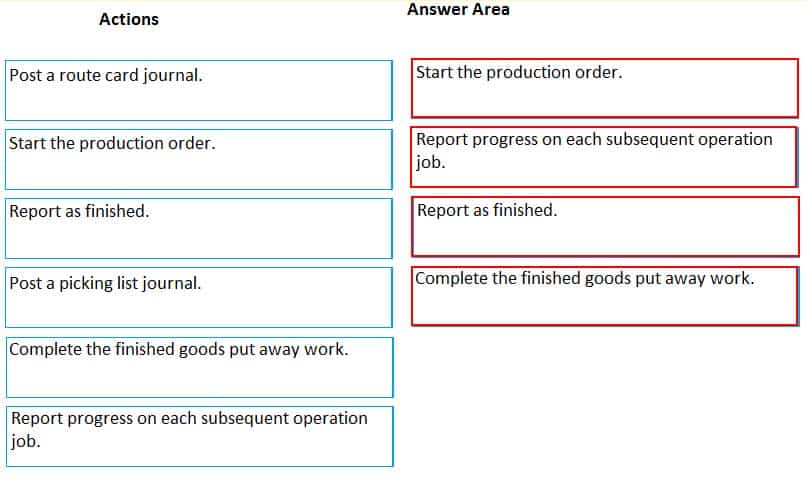

DRAG DROP

A company uses warehouse management and manufacturing execution to process their production orders.

You configure the manufacturing execution production order defaults to always consume Bill of materials (BOM) components when an operation step is completed in the job registration terminal. You create a production order. The order is in released status.

You need to process this order all the way through to end status.

Which four actions should you perform in sequence? To answer, check the appropriate actions to the answer area and arrange them in the correct order.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q20 047 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 04 Q20 047 Answer