MB-320 : Microsoft Dynamics 365 Supply Chain Management, Manufacturing : Part 06

MB-320 : Microsoft Dynamics 365 Supply Chain Management, Manufacturing : Part 06

-

A manufacturing company uses discreet manufacturing to make skateboards. Production order picking lists are manually posted after finished goods are reported as finished.

A production order has six picking lists posted. The quantities on the picking lists do not match any of the reported or finished quantities. This causes an inventory error for the raw materials. All raw material transactions must be tracked on production order and reconciled.

You need to process a single picking list for each production order.

What should you do first?

- Create a movement journal and select the proper account for production postings to reconcile the inventory that was posted in error

- Delete the six posted picking list journals

- Create a production picking list. When creating lines select option Full reversal.

- Create a counting journal to reconcile the inventory that was posted in error.

-

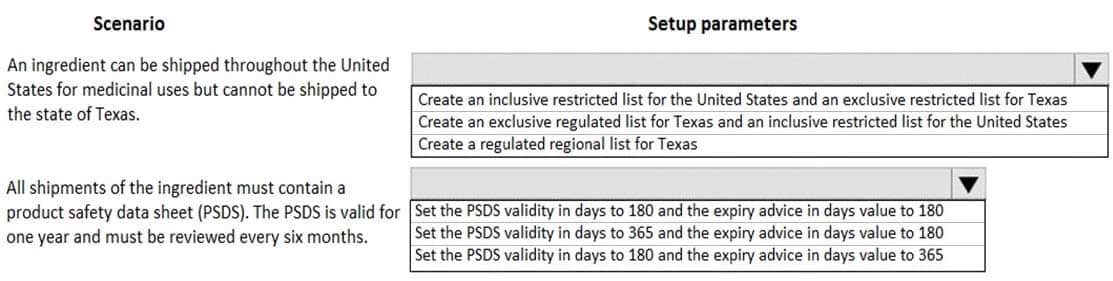

HOTSPOT

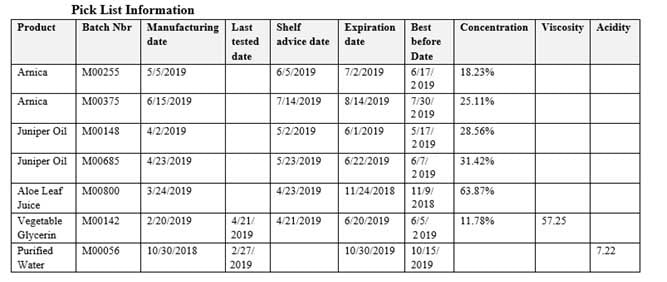

A company produces lotions for pain relief and uses Dynamics 365 Supply Chain Management.

You have been provided the following information for a new relieving lotion.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q02 060

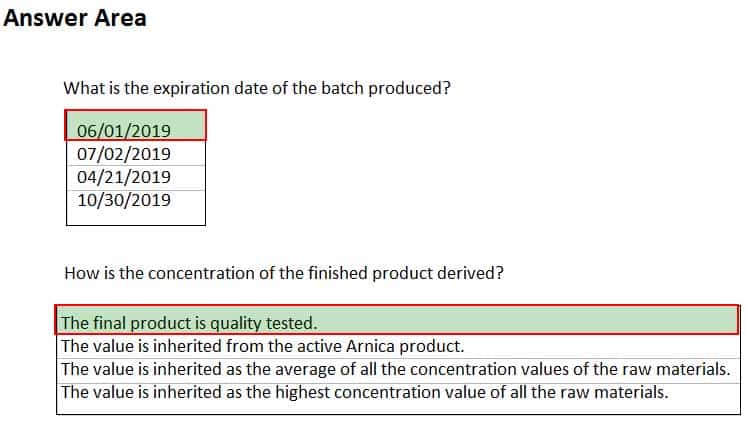

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q02 061 Use the drop-down menus to select the answer choice that completes each statement based on the information presented in the graphic.

NOTE: Each correct selection is worth one point.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q02 062 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q02 062 Answer -

A customer produces light projection toys for holiday decorations throughout the year. Vendors have negotiated rebate agreements as a condition of their contact. The contract also contains the visual templates required for the customer to use in a season.

Vendor rebate agreements must only be applied if the following requirements are met:

– Units of measure for deliverables are the same unit of measure as on the agreement

– The agreement is valid as of the date a purchase order is generatedYou need to configure the vendor rebate agreements.

What should you do?

- Set the Rebate line break type field value to Amount

- Set the Rebate line break type field value to Quantity

- Set the Cumulative purchase by field value to the beginning of the season date

- Set the Unit of measure rebate option field value to Exact match

-

A paint manufacturer is using Process manufacturing. The manufacturer has a quality error. Batches of paint that use the wrong formula have been marked for rework.

The production planner reports they cannot schedule the batch order even though the order has been estimated.

You need to add reservations to the items to be used for the rework order.

What should you do?

- Reserve the inventory in the formula

- Reset the batch order and delete the formula items. Re-enter the formula items

- Add by-products that need to be used and then re-estimate

- Add co-products that need to be used and then re-estimate

-

DRAG DROP

You are the product manager at a paint manufacturing company. Paint base is produced in 100 gallon batches. The paint base can be packaged in 1 gallon, 5 gallon, and 10 gallon containers.

You want to use consolidated batch orders for the bulk paint base item. You need to set up the items and formulas to allow for consolidated batch orders.

Which three actions should you perform in sequence? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q05 063 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q05 063 Answer -

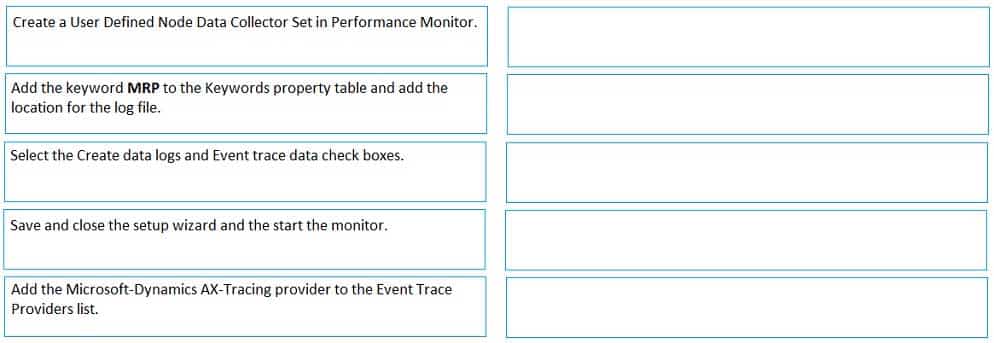

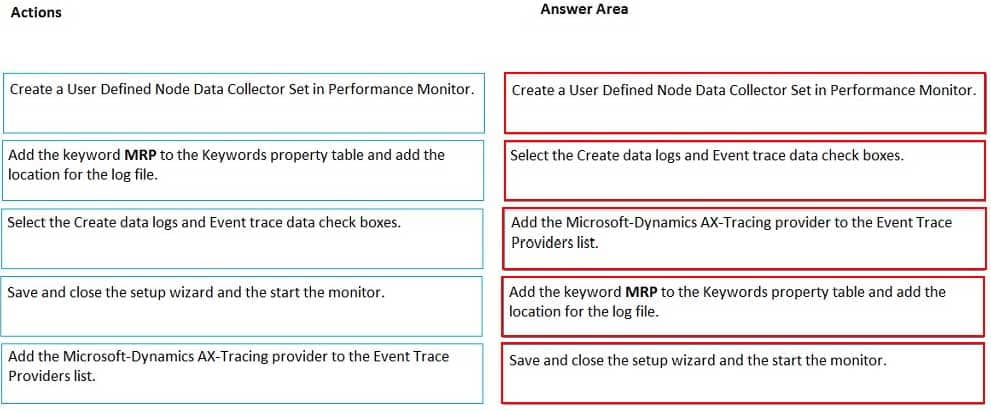

DRAG DROP

A company implements Dynamic 365 for Finance and Operations. You run the latest master plan. You observe invalid results.

You need to set up tracing for the master plan.

In which order should you perform the actions? To answer, move all actions from the list of actions to the answer area and arrange them in the correct order.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q06 064 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q06 064 Answer -

You are the lead product design engineer at a plastics manufacturing company. You implement a new process that uses a single tool to produce three finished goods at the same time.

You need to set up the planning item number and formula to correctly to manufacture the three items.

Which three actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

- Create item number for planning item and the associated formula

- Add minimum and maximum quantities on formula

- Add a coverage group to the formula

- Assign co-products to the formula

- Specify each of the finished good items as co-products

-

A company produces homeopathic lotions for pain relief and uses Dynamics 365 Supply Chain Management. You have replaced the vendor of a product’s active ingredient with a new vendor. The new vendor is supplying the ingredient at a higher concentration of 25 percent.

The previous vendor concentration was 15 percent. You are consistently running out of two of the complimentary ingredients.

You need to update the formula and ingredient settings to allow for better order planning.

What should you do?

- Modify the factor value of the compensation principle

- Modify the minimum and maximum value of the attribute for the active ingredient

- Modify the target value of the attribute for the compensating ingredients

- Modify the target value of the attribute for the active ingredient

-

You are the production scheduler at a manufacturing company. The company is not using advanced warehousing.

You have firmed a planned production order from master planning. The order is ready to be processed.

You now need to process the order in production control.

What should you do first?

- Report the order as finished

- Estimate the order

- Schedule the order

- Start the order

-

A company produces various products using Process manufacturing.

The manufacturer makes two co-products from a formula and rarely produces the primary formula item. The costs of making the co-products are inflated. The manufacturer must update the costs of producing the co-products and change the formula to not produce the primary formula item.

You need to change the primary formula item type.

What should you do?

- Associate the costs to produce by-products with the items

- Change the primary formula item to use the planning item type

- Change the cost of the primary formula item to zero and then recalculate the item cost

- Change the production type to Bill of materials and recalculate the item cost

-

A chemical manufacturing company uses Dynamics 365 Supply Chain Management. A batch of material has a quality issue and must be reworked.

You need to create the rework order the production.

Which three options must be set? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

- Reserve the reworked inventory after estimation

- Set the item as a Formula production type

- Specify the batch number of the batch order

- Set the batch order as a rework batch

- Pick the reworked inventory after estimation

-

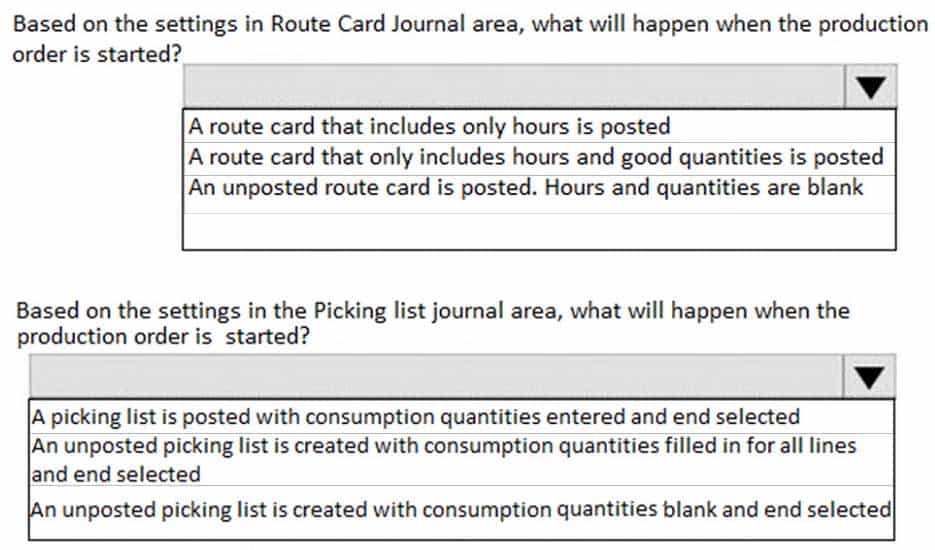

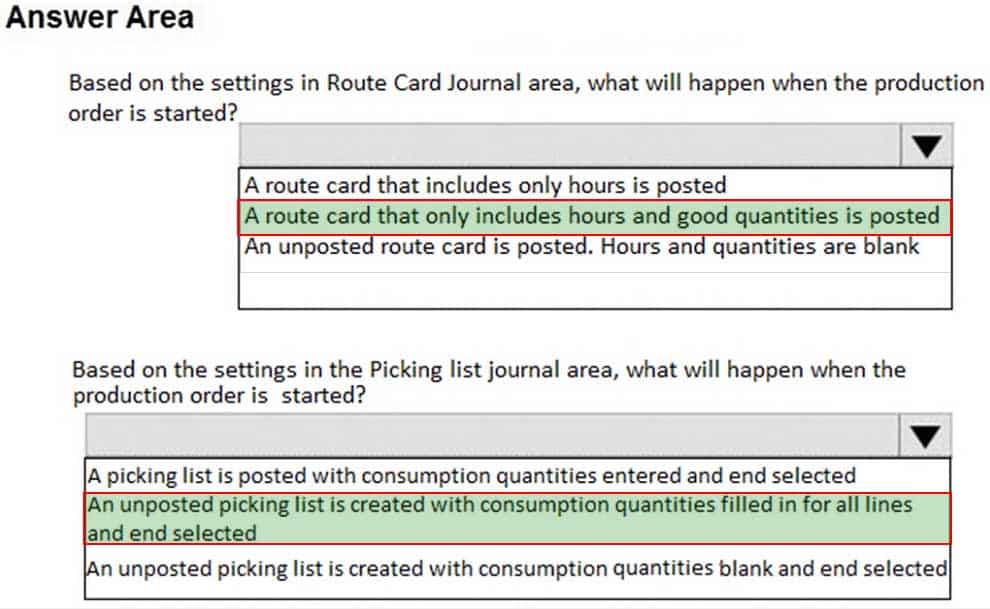

HOTSPOT

You are a manufacturing consultant helping a client test out different bill of material (BOM) and route consumption options when starting production orders. Material and labor consumption are to be completed before Report as finish.

You are running a production order with BOM lines that have a Flushing principle set to Start. The Automatic Route Consumption Runtime has been set to Yes.

You have set up the default Start user options for all production orders as shown in the exhibit below.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q12 065

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q12 066 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q12 066 Answer -

A customer produces light projection toys for holiday decorations throughout the year. The production process creates the projections toy at the following work cells stands, main assembly, electric, visuals, and packaging.

Vendors must create visual templates for the company for each season. They must manage the transfer of visual templates to the warehouse. Each transfer for each vendor must use the same purchase agreement.

You need to configure the subcontracted transfer activity.

What should you do?

- Set the transfer activity Freighted by value to Carrier. Ensure that purchase agreements include the vendor ID of the vendor.

- Set the transfer activity Freighted by value to Shipper. Ensure that purchase agreements include the vendor ID of the vendor.

- Set the transfer activity Freighted by value to Recipient. Ensure that purchase agreements include the vendor ID of the warehouse.

- Set the transfer activity Freighted by value to Carrier. Ensure that purchase agreements include the vendor ID of the warehouse.

- Set the transfer activity Freighted by value to Shipper. Ensure that purchase agreements include the vendor ID of the warehouse.

- Set the transfer activity Freighted by value to Recipient. Ensure that purchase agreements include the vendor ID of the vendor.

-

A manufacturer uses discreet orders and manually consumes raw material after reporting products as finished.

You are performing an end-of-month closing for remaining picking lists on production orders. You must not be required to consume the full amount of material on production order picking lists as a result of improved production efficiency. When the production manager verifies that no material is left to consume, there are remaining back-ordered amounts.

You need to pick the line item short and eliminate the remaining demand.

What should you do?

- Delete the item from the Bill of materials for the finished good.

- Enter the consumption amount on the line to match the actual amount used, and delete the remaining amount.

- Enter the consumption amount on the line to match the actual amount used and select end on the production order picking list.

- Change the Coverage group on item option to manual.

-

A company produces homeopathic lotions for pain relief. The lotions use a combination of Product A and Product B. Product A is the primary ingredient. You use Product B to adjust the concentration of active ingredients in the lotion.

You need to ensure that the lotion final product has a consistent concentration of anti-inflammatory agents.

Which two actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

- Set the formula line type of Product B to Active

- Set the formula line type of Product A to Active

- Set the formula line type of Product B to Compensating

- Set the formula line type of Product A to Compensating

- Set the formula line type of Product C to None

-

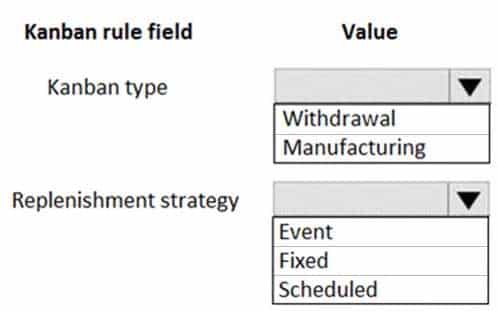

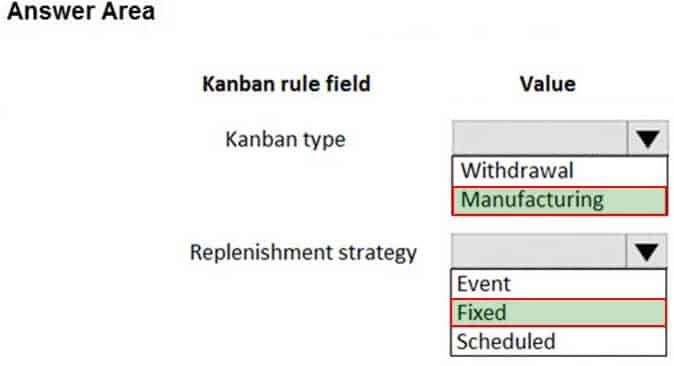

HOTSPOT

A company uses a make-to-stock strategy for their key production components.

The number of active Kanbans for these components must be constant.

You need to configure a new Kanban rule.

How should you set up the Kanban type and replenishment strategy? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q16 067 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q16 067 Answer -

HOTSPOT

A company produces homeopathic lotions for pain relief and uses Dynamics 365 Supply Chain Management.

Several components used in the production of the pain-relieving lotion and oils have special government-mandated reporting requirements.

You need to ensure the company can provide the appropriate reporting and tracking for these components.

Which parameters should you use? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q17 068 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q17 068 Answer -

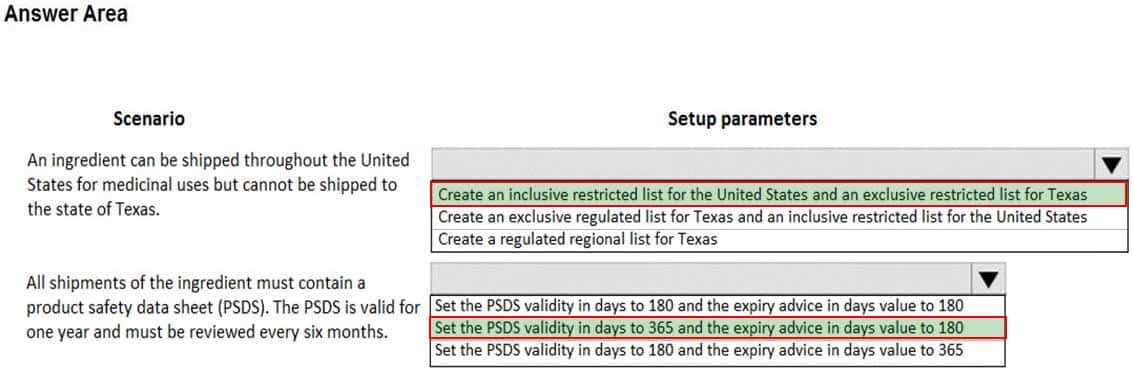

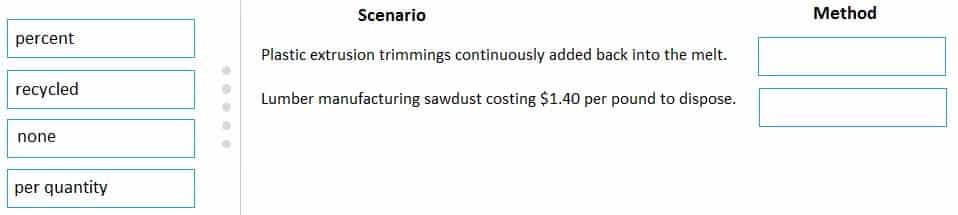

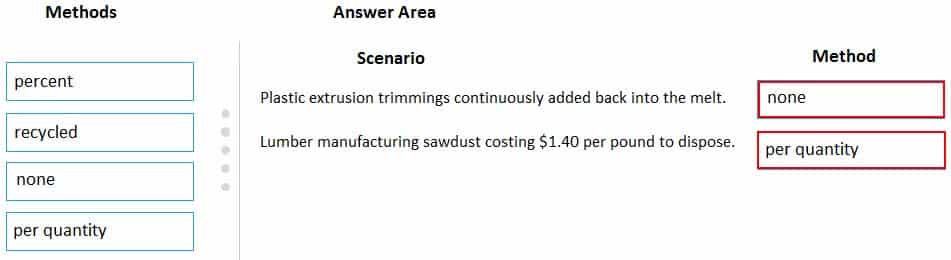

DRAG DROP

A process manufacturing company is implementing Dynamics 365 Supply Chain Management. The company will use multiple process manufacturing functionalities including by-products..

You need to configure by-product formula allocation methods.

Which methods should you use? To answer, drag the appropriate by-product burden allocation methods to the correct scenarios. Each method may be used once, more than once, or not at all. You may need to drag the split bar between panes or scroll to view content.

NOTE: Each correct selection is worth one point.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q18 069 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q18 069 Answer -

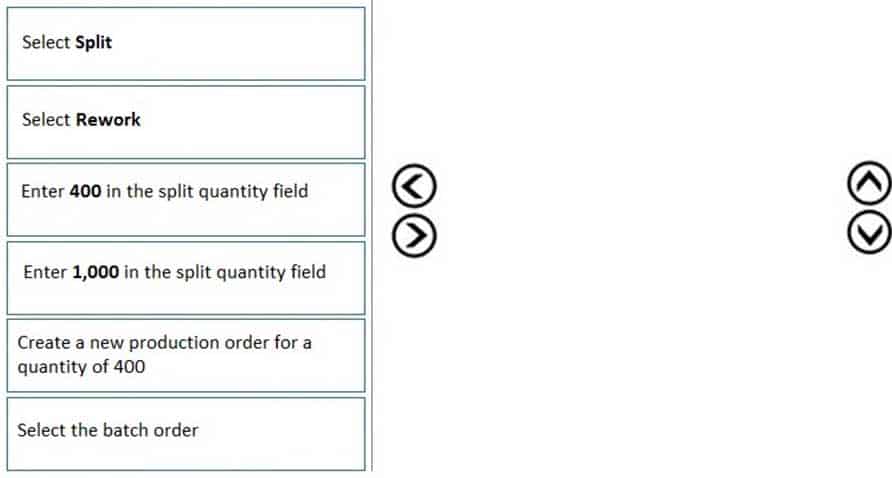

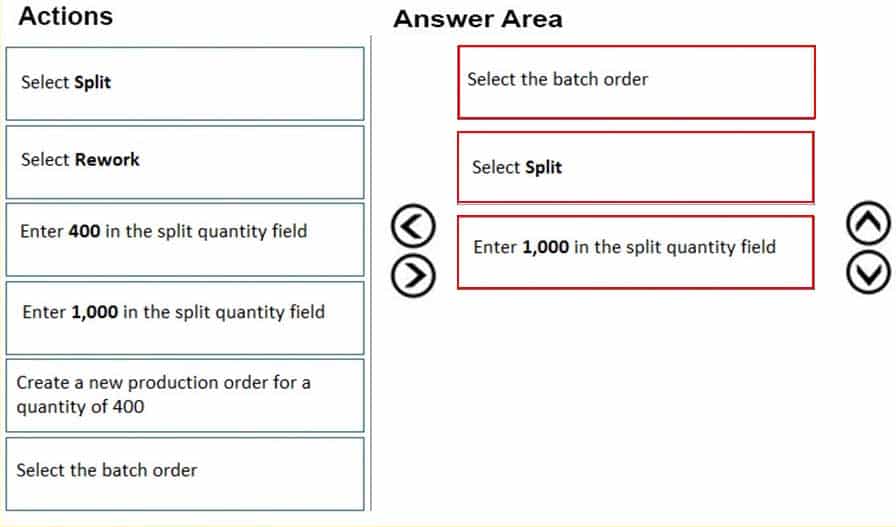

DRAG DROP

A company uses Dynamics 365 Process manufacturing.

Employees work a half day so that they can attend a company event. You have a rush order that must be completed that same day.

After reviewing the net requirements of the batch order, only 400 of the total quantity of 1400 units must be completed today. The production manager must retain the original batch number as the quantity of 400. The original batch number must appear on documentation for the customer.

You need to split the batch order onto two orders.

Which three actions should you perform in sequence? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q19 070 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 06 Q19 070 Answer -

A company sells large batches of chemicals. Item specifications vary from batch to batch.

You must fulfill multiple orders from the same batch of chemicals. If a single batch cannot be reserved, manual reservation must be used. The system must also make reservations based on the earliest batch receipt date.

You need to set up a new chemical item that automatically uses the new batch reservation logic.

Which three settings should you configure? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

- In the Tracking dimension group, select Coverage plan by dimension for batch number

- In the Item model group, select FEFO date-controlled

- In the Item model group, select the FIFO inventory model

- In the Item model group, select Same batch reservation and Consolidate requirements

- In the storage dimension group, select Coverage plan by dimension for the site and warehouse dimensions