MB-320 : Microsoft Dynamics 365 Supply Chain Management, Manufacturing : Part 07

MB-320 : Microsoft Dynamics 365 Supply Chain Management, Manufacturing : Part 07

-

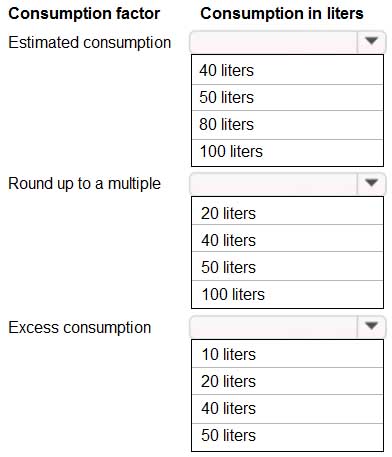

A company uses Process manufacturing for most products and Discreet manufacturing for other products. The company is creating a formula for a new product. The new item will be used to make a name brand product and two generic brand products.

This item has the following requirements:

– Production of the name brand and generic products must use the same formula.

– The company must produce all three items at the same time.You need to create a produced item that can make two generic items and one main item.

How should you set up the item?

- Create the name brand product as the main product and use a formula production type.

Create the two generic items as a formula planning production type planning items.

Copy the formula from the name brand item into each of the generic items. - Create the name brand product as the main product and use a formula production type.

Create the two generic products as co-products as part of the formula for the name brand product. - Create the name brand item as a Bills of material production type item.

Create the two generic items as a sub-assembly on the Bills of material for the name brand product. - Create the name brand item as a Bills of material production type item.

Add the two generic items on the Bills of material for the name brand product and use line type phantom.

- Create the name brand product as the main product and use a formula production type.

-

You are the lead product design manager at a Process manufacturing plant.

You are building a formula that produces egg yolks as a by-product. This by-product is added back into inventory at standard cost and can be used in other production batches.

You need to select the by-product cost allocation.

Which cost allocation type should you use?

- Per series

- Per quantity

- Recycled

- Percent

-

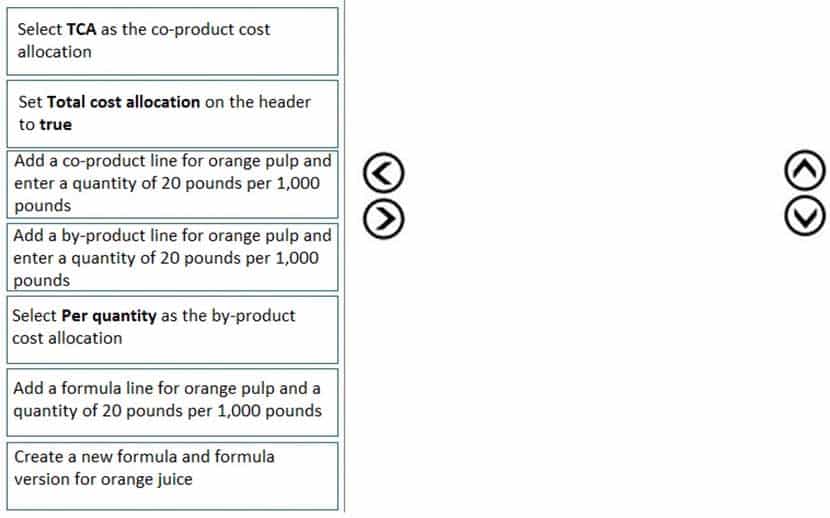

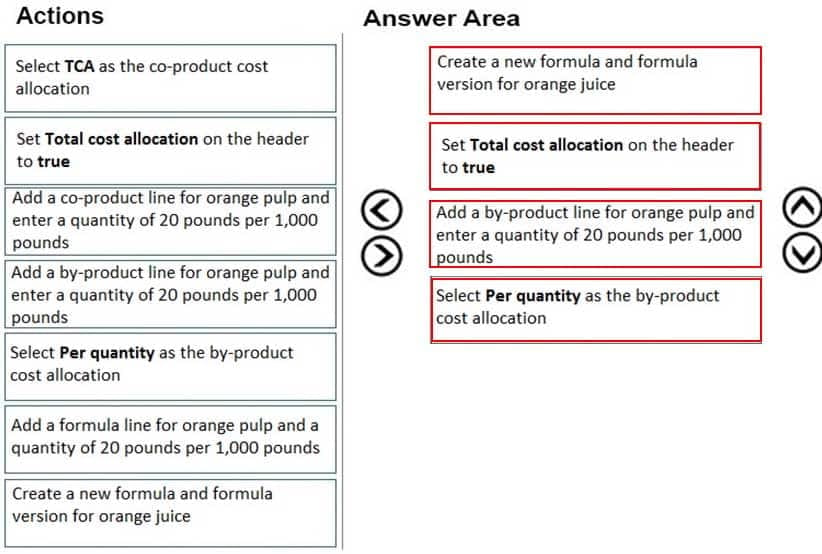

DRAG DROP

You are the product manager at an orange juice manufacturing company.

For every 1,000 pounds of orange juice, 20 pounds of orange pulp is created which can be sold or reused profitably. The cost is calculated as a weighted average between the quantity of orange juice that is reported as finished and the orange pulp based on the standard cost of each item.

You need to create the formula for orange juice that will produce orange pulp as a result of finishing a batch order.

Which four actions should you perform in sequence? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q03 071 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q03 071 Answer -

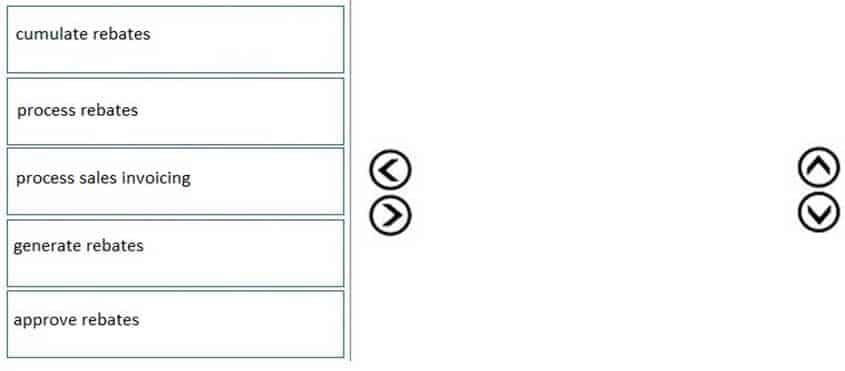

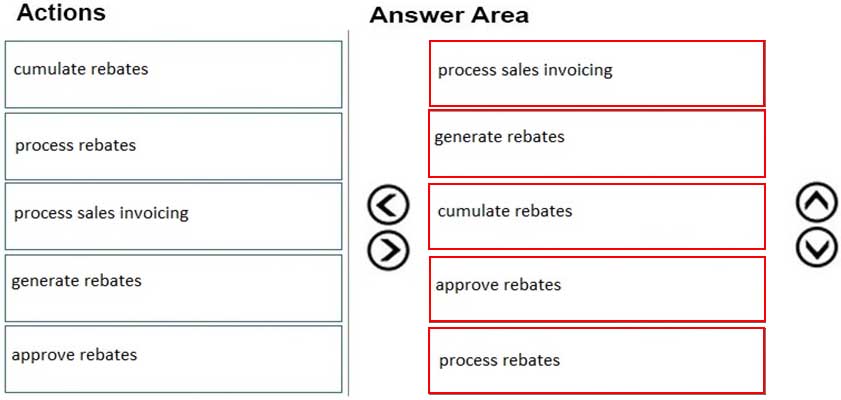

DRAG DROP

A process manufacturing company is implementing rebates in Dynamics 365 Supply Chain Management for some of their customers on specific items.

You are the production consultant in charge of implementing the processes needed for calculating and applying the rebates for the subset of customer and items.

You need to implement the order of transactions to process the rebates.

In which order should the actions be performed? To answer, move all actions from the list of actions to the answer area and arrange them in the correct order.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q04 072 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q04 072 Answer -

A beverage company uses Dynamics 365 Supply Chain Management batch processing for production.

You need to identify the ingredient type used in batch processing when the base attribute of a product is added to a formula line.

What is the ingredient type?

- filler

- active

- compensating

- none

-

Note: This question is part of series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some question sets might have more than one correct solution, while others might not have a correct solution.

After you answer a question in this section, you will NOT be able to return to it. As a result, these questions will not appear in the review screen.

A manufacturing plant uses batch tracking of raw materials, semi-finished goods, and finished goods.

It is difficult to determine when semi-finished and finished goods were produced and expired.

You need to incorporate automatic batch expiration dates for tracked items that are produced.

Solution:

1. Assign shelf life period in days to the items that require expiration dates.

2. Create a new batch number in the tracking dimensions for the items.

3. Enter the manufacturing date.

4. Save the record.Does the solution meet the goal?

- Yes

- No

-

Note: This question is part of series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some question sets might have more than one correct solution, while others might not have a correct solution.

After you answer a question in this section, you will NOT be able to return to it. As a result, these questions will not appear in the review screen.

A manufacturing plant uses batch tracking of raw materials, semi-finished goods, and finished goods.

It is difficult to determine when semi-finished and finished goods were produced and expired.

You need to incorporate automatic batch expiration dates for tracked items that are produced.

Solution:

1. Assign shelf life period in days to the items that require expiration dates.

2. Create a new reservation hierarchy that places batch at one.

3. Assign the new reservation hierarchy to the items that require expiration dates.Does the solution meet the goal?

- Yes

- No

-

Note: This question is part of series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some question sets might have more than one correct solution, while others might not have a correct solution.

After you answer a question in this section, you will NOT be able to return to it. As a result, these questions will not appear in the review screen.

A manufacturing plant uses batch tracking of raw materials, semi-finished goods, and finished goods.

It is difficult to determine when semi-finished and finished goods were produced and expired.

You need to incorporate automatic batch expiration dates for tracked items that are produced.

Solution:

1. Create a new batch number group that includes production activation in the settings.

2. Assign the group to the produced items.

3. Assign shelf life period in days to the items that require expiration dates.Does the solution meet the goal?

- Yes

- No

-

SIMULATION

You are a functional consultant for Contoso Entertainment System USA (USMF).

You need to configure the system to ensure that production purchases are grouped by purchase agreement.

To complete this task, sign in to Dynamics 365 portal.

- See explanation below.

Explanation:1. Navigate to the Master Planning Parameters form (Master Planning > Setup > Master Planning Parameters).

2. Select the Standard Update tab.

3. Select the Group by purchase agreement option. This option will also automatically select the 4. Find purchase agreements option.

Save the changes. -

SIMULATION

You are a functional consultant for Contoso Entertainment System USA (USMF).

You need to configure the system to ensure that planned master orders generated by Material Requirements Planning (MRP) contain trade agreements.

To complete this task, sign in to Dynamics 365 portal.

- See explanation below.

Explanation:1. Navigate to the Master Planning Parameters form (Master Planning > Setup > Master Planning Parameters).

2. Select the Planned Orders tab.

3. Select the Find Trade Agreements option.

4. Save the changes. -

SIMULATION

You are a functional consultant for Contoso Entertainment System USA (USMF).

You need to schedule the Material Requirements Planning (MRP) master plan to run nightly at 03:00 (UTC-8).

To complete this task, sign in to Dynamics 365 portal.

- See explanation below.

Explanation:You need to configure a batch job to run the master plan nightly.

Create the batch job

1. Go to Navigation pane > Modules > System administration > Inquiries > Batch jobs.

2. Click New.

3. In the Job description field, type a value.

4. In the Scheduled start date/time field, enter a date and time.

5. Click Save.Create a recurrence

1. On the Action Pane, click Batch job.

2. Click Recurrence. Use these options to enter a range and pattern for the recurrence.

3. Click OK. - This is a case study. Case studies are not timed separately. You can use as much exam time as you would like to complete each case. However, there may be additional case studies and sections on this exam. You must manage your time to ensure that you are able to complete all questions included on this exam in the time provided.

To answer the questions included in a case study, you will need to reference information that is provided in the case study. Case studies might contain exhibits and other resources that provide more information about the scenario that is described in the case study. Each question is independent of the other question on this case study.

At the end of this case study, a review screen will appear. This screen allows you to review your answers and to make changes before you move to the next section of the exam. After you begin a new section, you cannot return to this section.

To start the case study

To display the first question on this case study, click the Next button. Use the buttons in the left pane to explore the content of the case study before you answer the questions. Clicking these buttons displays information such as business requirements, existing environment, and problem statements. If the case study has an All Information tab, note that the information displayed is identical to the information displayed on the subsequent tabs. When you are ready to answer a question, click the Question button to return to the question.Background

General information

A manufacturing company produces custom configured-to-order motorcycles. The company plans to implement Dynamics 365 Supply Chain Management. The company contains one legal entity located in Missouri where all production and warehousing operations occur.

Customization options

The custom motorcycles have a variety of selections that can be selected in the listed order by the end customer, including the following:

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q12 073 Current environment

Customization restrictions

The following restrictions on customizations are in place:

– Green color can only be sold with the Legend Trim.

– Orange color can be sold with the Sport or Legend Trim.

– The ML seat must be included in the Legend package.

– The MS seat must be included in the Sport package.Manufacturing facilities

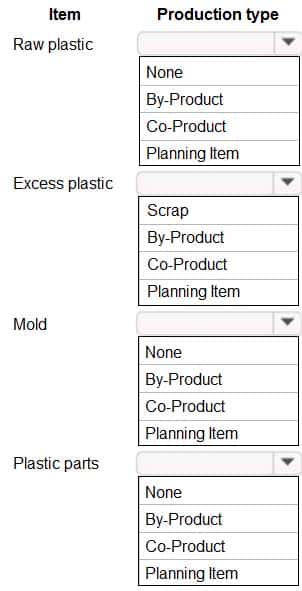

The company includes the following manufacturing groups: Assembly and Plastic Molding. The Assembly group is responsible for assembling the motorcycles with purchased and manufactured goods. The Plastic Molding group is responsible for manufacture of all plastic parts used in the assembly area.

Motorcycle manufacturing

The parts for the product assembly are picked from the warehouse and staged at the correct workstation by a warehouse operator for each production order.

Plastic manufacturing

Plastic parts are molded using dyes that create multiple parts at once. The parts are machined in the same production process to remove excess plastic and add additional holes for assembly. Excess plastic is recycled back into the feedstock of the same color plastic chips for use in the molding process.

Metal parts

Raw metal parts are purchased fully machined but without primer or paint. The parts are subcontracted to a vendor for primer and paint based upon the color requirements.

Facility

The company has a single warehouse that supports both the assembly and plastic manufacturing areas. The warehouse consists of three aisles with 15 bins and three shelves. The facility has no Wi-Fi capacity but has hardwired terminal stations throughout the assembly production line.

Transactions are currently completed by office staff. Raw materials transfer must support capacity constraints for paint and primer.

Requirements

Sales orders

The company has the following requirements for sales orders:

– During the configuration of a sales order, invalid combinations must be prevented.

– Each configuration must create a unique bill of material (BOM) and Route based on options selected.

– Sales pricing for the sales order must be based upon options selected.

– Due to emissions regulations, the motorcycles cannot be sold to the state of California.Motorcycle manufacturing

The company has the following requirements for motorcycle manufacturing:

– Schedule labor only at the labor pool level without machines by day.

– Produce motorcycles within a scheduled day in any order.

– Record actual production labor with start/stop times.

– Record manager approval of labor entered prior to posting.

– Post actual material consumption after production is finished.Plastic manufacturing

The company has the following requirements for motorcycle manufacturing:

– Schedule both labor and machines.

– Adjust schedules by using a Gantt chart.

– Backflush standard labor by operation.

– Post actual material consumption at the start of production.

– Track and allocate costs to the excess plastic.

– Report multiple molded part numbers during the same production run.

– Determine the correct mold to use on a production order.

– Generate a batch number for each production order.Current environment

Metal parts

The company has the following requirements for metal parts manufacturing:

– Schedule shipments to the vendor for painting.

– Receive painted parts into inventory from the vendor.

– Track vendor inventory levels.Defaults

You must configure defaults for manufacturing execution production orders to meet the following requirements:

– Ensure accuracy for production order pick list posting.

– Ensure correct pick list creation.Issues

– In the current system, the company cannot calculate overhead rates and determine the breakdown of material, labor, machine, and overhead costs for production.

– The company is manually calculating an 8% overhead on materials and posting a journal manually.-

HOTSPOT

You need to configure each item for plastic manufacturing.

Which production types should you use? To answer, select the appropriate option in the answer area.

NOTE: Each correct selection is worth one point.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q12 074 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q12 074 Answer -

You need to set up the state control for sales of motorcycles.

Which two actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

- Create an inclusive restricted product list for United States. Do not add the motorcycle part to the list.

- Create an inclusive restricted product list for United States and add the motorcycle part to the list.

- Create an exclusive restricted product list for California and add the motorcycle part to the list.

- Create an exclusive restricted product list for Missouri and add the motorcycle part to the list.

-

- This is a case study. Case studies are not timed separately. You can use as much exam time as you would like to complete each case. However, there may be additional case studies and sections on this exam. You must manage your time to ensure that you are able to complete all questions included on this exam in the time provided.

To answer the questions included in a case study, you will need to reference information that is provided in the case study. Case studies might contain exhibits and other resources that provide more information about the scenario that is described in the case study. Each question is independent of the other question on this case study.

At the end of this case study, a review screen will appear. This screen allows you to review your answers and to make changes before you move to the next section of the exam. After you begin a new section, you cannot return to this section.

To start the case study

To display the first question on this case study, click the Next button. Use the buttons in the left pane to explore the content of the case study before you answer the questions. Clicking these buttons displays information such as business requirements, existing environment, and problem statements. If the case study has an All Information tab, note that the information displayed is identical to the information displayed on the subsequent tabs. When you are ready to answer a question, click the Question button to return to the question.Current environment

Products manufactured

– Cleaning equipment

– floor cleaner

– pressure washers

– scrubbers

– vacuums

– Liquid cleaning solutions

– No scent

– Orange scent (subcontracted to a vendor named Vendor A)

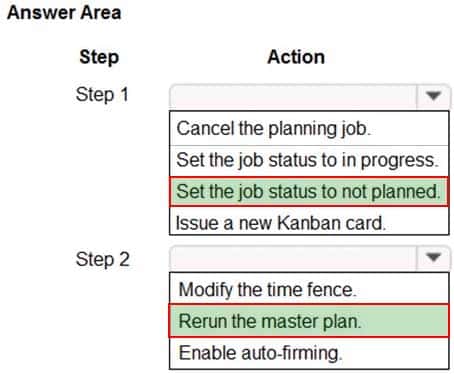

– Pine scent (subcontracted to a vendor named Vendor A)The production quantity for the finished unscented liquid cleaning solution is 40-liters. Ingredient C for unscented liquid cleaning solution is stored in inventory in 50-liter barrels and allocated in 50-liter increments. Two barrels of Ingredient C are used to produce a barrel of unscented liquid cleaning solution.

Current environment

Production sites

The Eastern United States facility manufactures equipment.

The Western United States facility manufactures liquid cleaning solutions.

Raw materials and finished products are stocked at the warehouse and distributed from the warehouse.Warehouse facilities

The warehouse consists of the following zones:

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q13 075 Requirements

Cleaning equipment manufacturing

You identify the following requirements for manufacturing cleaning equipment:

– Production is Make to Stock and must be scheduled at an operational level.

– Machine equipment is produced on an assembly line. Scheduling must be based on production orders.

– Finished products must be packaged and shipped directly from the warehouse.

– To reduce delivery times and excess inventory, equipment must be produced as needed.

– The ability to schedule production must be based on resource capacity and the availability of required material.

– Production order operations must be scheduled to start only when capacity and materials are available at the same time and in the required quantities.Liquid cleaning solution manufacturing

– Production is Make to Order and is scheduled at the job level Products must be manufactured in batches.

– Finished products must be packaged and shipped directly from the warehouse.

– You must be able to calculate the estimated consumption of ingredients and ensure that the amount is divisible by the number of units the raw material is available.

– Formula changes must be reviewed and approved. You must ensure that approved formulas cannot be deleted or edited. Approved formulas may be deactivated.

– An ingredient used to manufacture unscented cleaning solution is defined as a restricted product. You must be able to automatically print a product safety data sheet (PSDS) with the packing slip for any order that includes unscented cleaning solution.

– Production must be schedule to start by date and time according to the order that is specified by the production route.

– You must implement a scheduled Kanban rule that meets the following requirements:

– Prevent overloading a work cell for scheduled Kanbans.

– Visualize excess inventory in a supermarket.

– Store products in supermarkets before they are consumed or shipped.

– You must link relevant financial dimension data to the inventory transactions at each site to ensure that you can trace profit and loss figures directly to East site and West site respectively.

– You must set up production operations for sub-contracting of Pine scent and Orange scent solution to VendorA to ensure that a purchase order is automatically created base on estimation of a production order.Costing

– The price of raw materials used for manufacturing unscented cleaning solution must be tracked based upon commodity exchange pricing. The margin and cost multiplier must be set up for commodity traded raw material.

– You must set up cost calculation groups to ensure that indirect costs that originate in the manufacturing of finished goods are recognized and absorbed into the product cost.

– The production manager needs to set up picking list journals and BOM item consumption.Reporting

– Production control parameters must be setup for reporting of automatic BOM and Route consumption.

– You must create reports that include information about cost records and categories for items, and calculation formulas for indirect costs.

– You must treat manufactured items as purchased items for cost roll-up purposes during BOM calculations and reporting.

– You must configure automatic route consumption in connection with the automatic running of Report as finished.Inventory control

You must not be required to track the lot number for items when you enter inventory information into the system. Lot numbers for items must be entered when items are picked from inventory.

Issues

Users report the following issues:

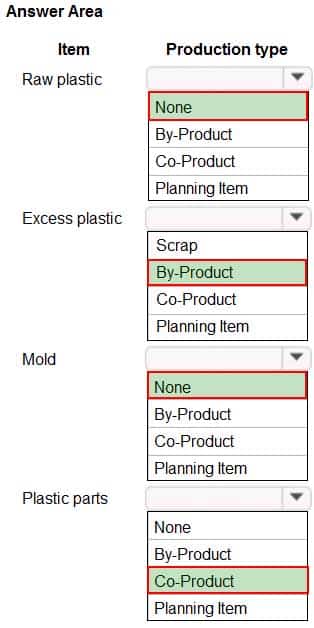

– The production manager observes that items are being deducted from inventory two times on production jobs. A shop supervisor mistakenly registers the process for assembling batteries for the pressure washers to Registered as prepared. You must reschedule the process for a future date.

– Customer1 orders 20 barrels of unscented solution. The order is confirmed. Production must be scheduled to start on December 21 to meet the customers delivery deadline.

– User2 reports that costs for manufactured items are twice as high as expected.

– User D reports that the formula for the liquid cleaning solution sometimes changes during production. You must enforce the policies regarding formula editing for current and future use.-

HOTSPOT

You need to resolve the production manager issue.

How should you configure manufacturing execution? To answer, select the appropriate option in the answer area.

NOTE: Each correct selection is worth one point.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q13 076 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q13 076 Answer -

HOTSPOT

You need to resolve the shop supervisor’s issue.

Which options should you use? To answer, select the appropriate option in the answer area.

NOTE: Each correct selection is worth one point.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q13 077 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q13 077 Answer -

HOTSPOT

You need to calculate estimated consumption of ingredients for liquid cleaning solution.

What is the consumption? To answer, select the appropriate option in the answer area.

NOTE: Each correct selection is worth one point.

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q13 078 Question

MB-320 Microsoft Dynamics 365 Supply Chain Management, Manufacturing Part 07 Q13 078 Answer

-