MB-330 : Microsoft Dynamics 365 Supply Chain Management : Part 08

MB-330 : Microsoft Dynamics 365 Supply Chain Management : Part 08

-

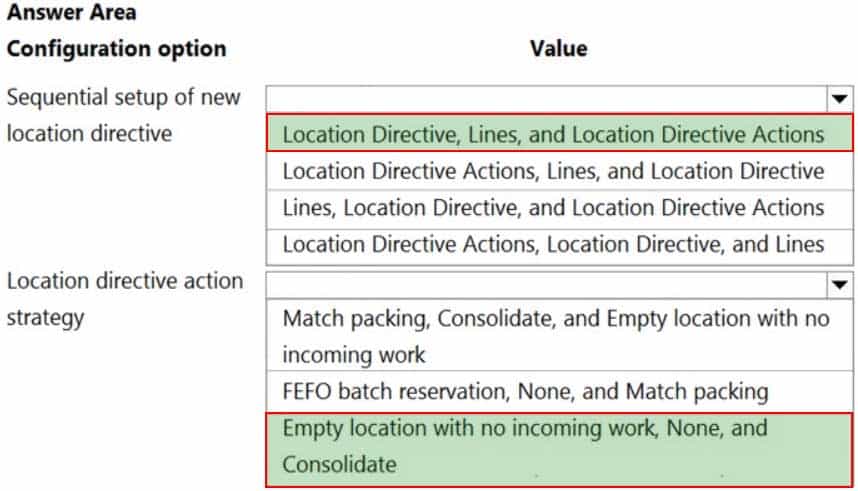

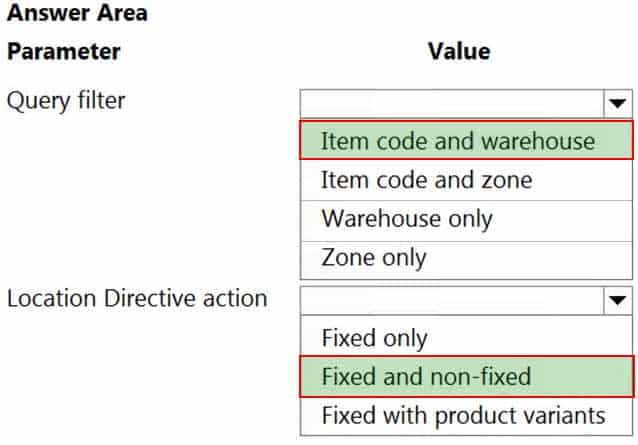

HOTSPOT

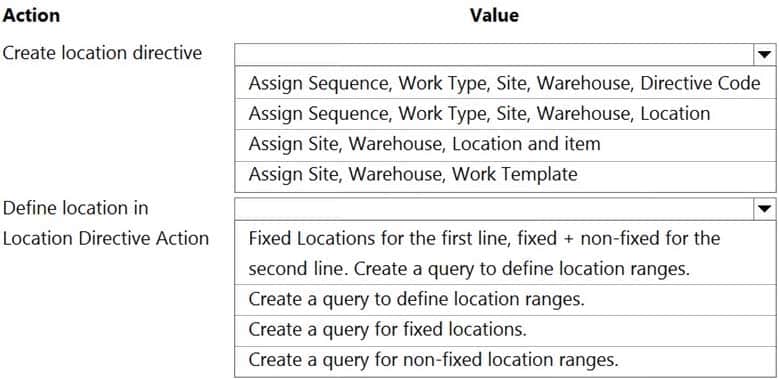

A company needs to stock inventory in their warehouse. Inbound purchase order materials may need to be placed into more than one location in the warehouse.

You need to configure placement for inventory in the warehouse.

How should you set up location directives? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q01 076 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q01 076 Answer -

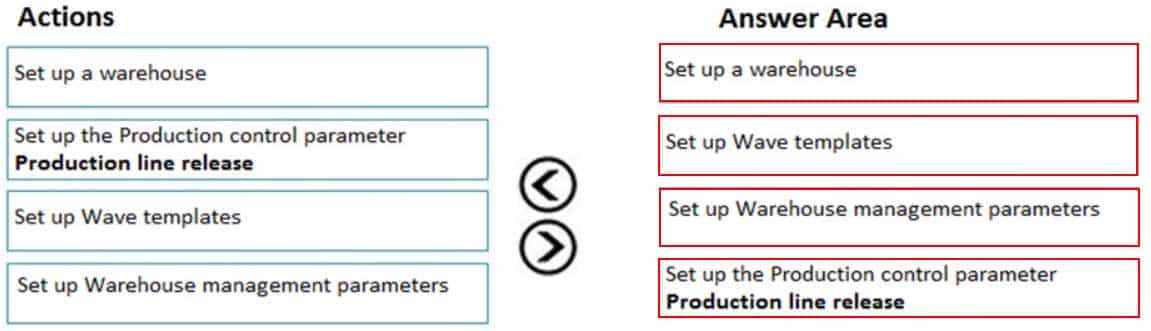

DRAG DROP

A company uses the Dynamics 365 Supply Chain Management Warehouse management module.

The company requires production waves to be processed in batch.

You need to configure wave processing.

In which order should you perform the actions? To answer, move all actions from the list of actions to the answer area and arrange them in the correct order.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q02 077 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q02 077 Answer -

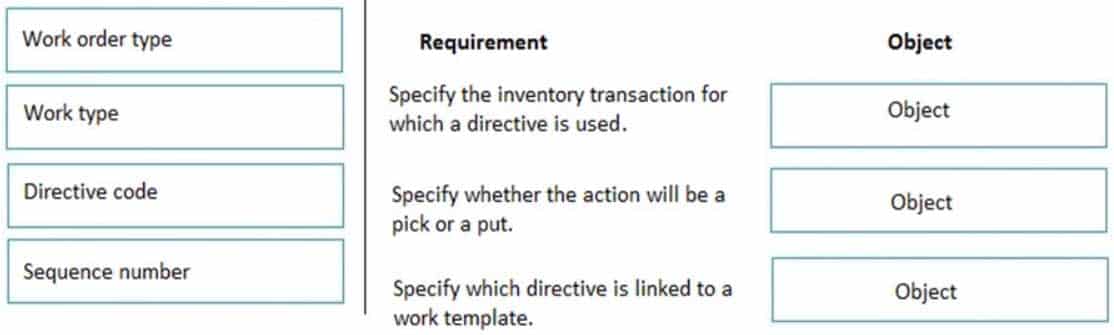

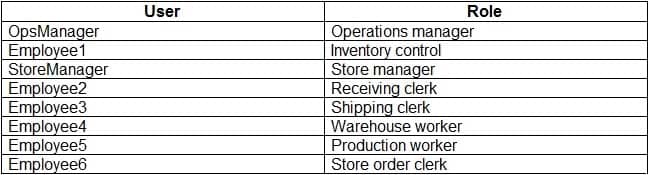

DRAG DROP

You need to implement location directives in Dynamics 365 Supply Chain Management.

Which objects should you use? To answer, drag the appropriate objects to the correct permissions. Each object may be used once, more than once, or not at all. You may need to drag the split bar between panes or scroll to view content.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q03 078 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q03 078 Answer -

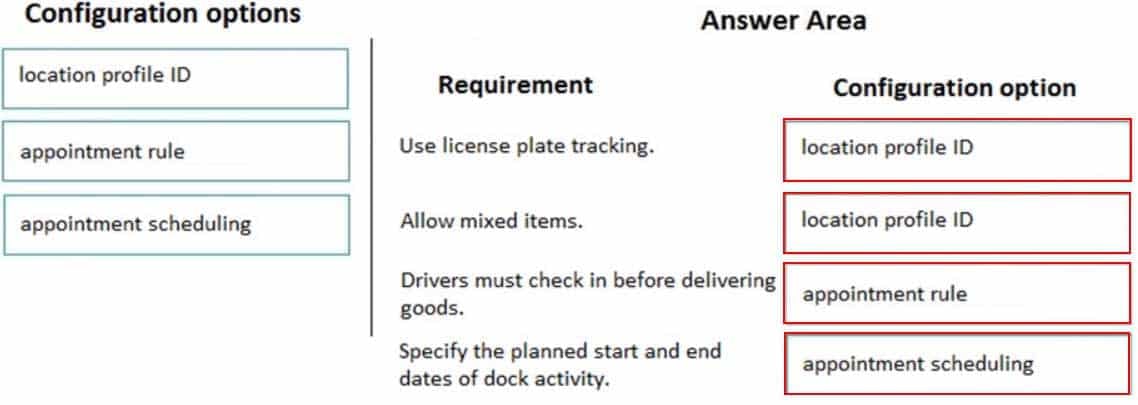

DRAG DROP

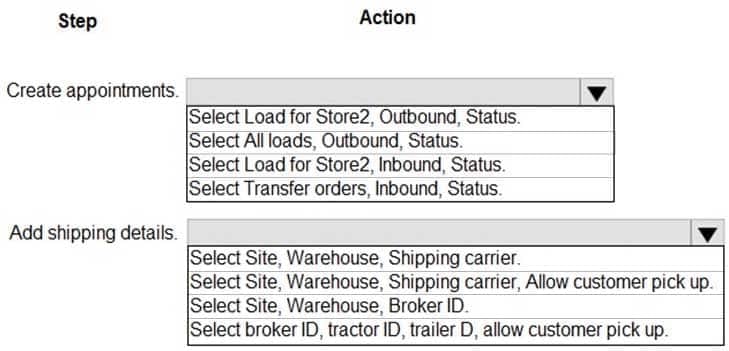

A company plans to use warehouse management and dock appointment scheduling in Dynamics 365 Supply Chain Management.

You need to configure the system.

Which configuration options should you use? To answer, drag the appropriate configuration options to the correct requirements. Each configuration option may be used once, more than once, or not at all. You may need to drag the split bar between panes or scroll to view content.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q04 079 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q04 079 Answer -

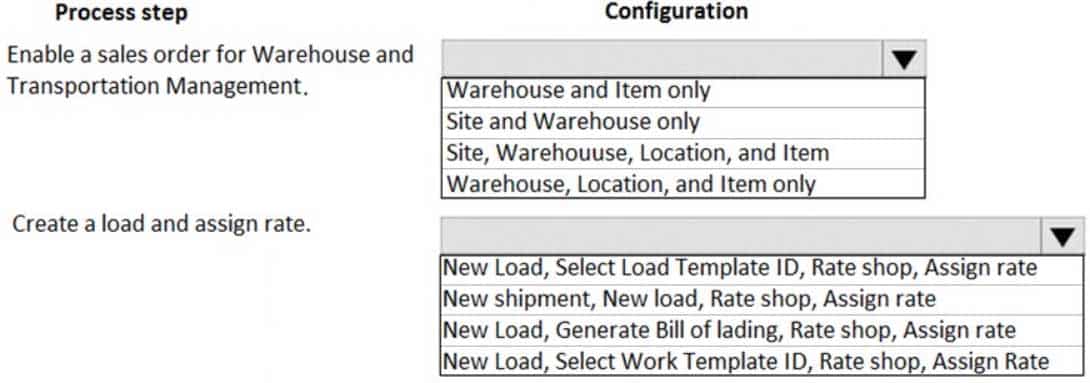

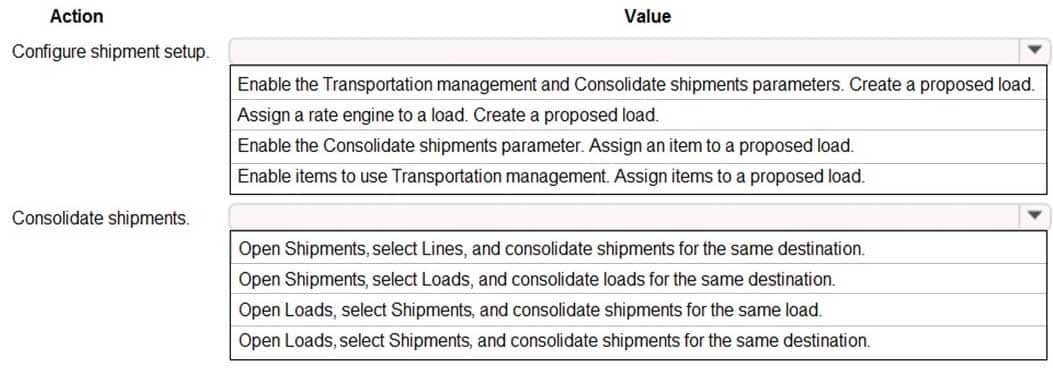

HOTSPOT

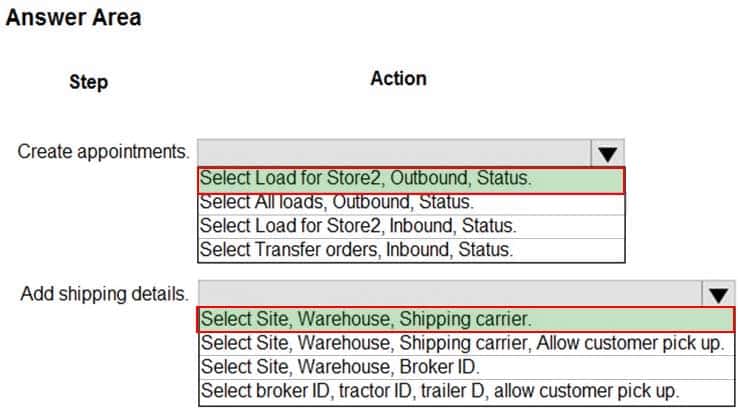

A company creates loads to ship sales orders.

Loads must be shipped by using the lowest freight rates possible.

You need to use the load planning workbench to create a load for sales order shipments.

Which configuration options should you use? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q05 080 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q05 080 Answer -

You are the logistics manager at a distribution company.

Your primary carrier service provides rates for transportation between New York City and Colorado. These rates are a flat rate depending on the city or general area of pickup as follows:

– New York City = $500

– Colorado = $450You need to set up Transportation Management to calculate the rate from New York City to Colorado.

What should you do?

- Use a Point-to-Point engine based on weight and miles. Assign rates from New York City as the starting location and Colorado as the ending location and break the rates out based on the weight of the package.

- Use a mileage-based rate engine to configure a rate master that calculates the rate based on the miles from New York City to Colorado.

- Create hubs for both locations. Add a route plan from New York City to Colorado and assign the two charges as spot rates.

- Set up zones in the Zone Master for New York City and Colorado. Assign rates to each zone in the Zone Master by starting and ending location.

-

HOTSPOT

A company must set up replenishment of inventory using vendor-owned consignment inventory.

You need to create the replenishment order.

How should you complete the replenishment order? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q07 081 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q07 081 Answer -

A warehouse picks and ships product.

The warehouse completes work immediately upon automatic release to the warehouse.

You need to configure waves to allow for automatic work creation.

What should you do?

- Select the wave template and attribute to automatically process.

- Release to warehouse and process the work.

- Automate wave creation and process the wave at release to warehouse.

- Automate wave creation and automatically process work.

-

DRAG DROP

A company plans to implement Dynamics 365 Supply Chain Management mobile device connectivity.

You need to perform a spot cycle count on the mobile device.

Which three actions should you perform in sequence? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q09 082 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q09 082 Answer -

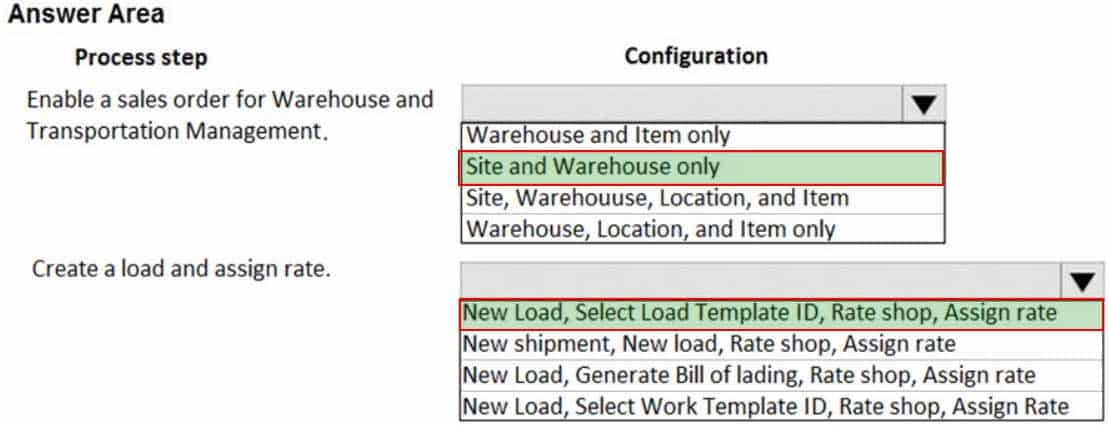

DRAG DROP

A company uses Dynamics 365 Supply Chain Management with basic warehouse processes. Mobile devices are not used in the two warehouses. Warehouse items that have an A classification are counted weekly through automatic cycle count journals that are created per warehouse.

Items that are in both warehouses appear only in one journal for counting. Counts are inaccurate because picking is posted against items that are being counted.

You need to resolve the cycle count issues. To answer, drag the appropriate configurations to the correct requirements. Each configuration may be used once, more than once, or not at all. You may need to drag the split bar between panes or scroll to view content.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q10 083 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q10 083 Answer -

You are implementing warehousing in Dynamics 365 Supply Chain Management.

You need to configure and approve one warehouse that can be used to create additional warehouses.

What should you use?

- inventory and warehouse management parameter setup

- warehouse management parameter setup only

- warehouse work template

- warehouse configuration template

-

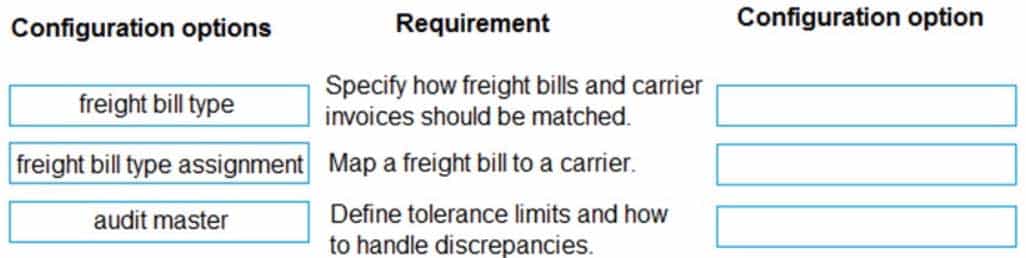

DRAG DROP

A client uses Dynamics 365 Supply Chain Management.

You need to configure automatic freight reconciliation.

Which configuration options should you use? To answer, drag the appropriate configuration options to the correct requirements. Each configuration option may be used once, more than once, or not at all. You may need to drag the split bar between panes or scroll to view content.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q12 084 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q12 084 Answer - This is a case study. Case studies are not timed separately. You can use as much exam time as you would like to complete each case. However, there may be additional case studies and sections on this exam. You must manage your time to ensure that you are able to complete all questions included on this exam in the time provided.

To answer the questions included in a case study, you will need to reference information that is provided in the case study. Case studies might contain exhibits and other resources that provide more information about the scenario that is described in the case study. Each question is independent of the other questions in this case study.

At the end of this case study, a review screen will appear. This screen allows you to review your answers and to make changes before you move to the next section of the exam. After you begin a new section, you cannot return to this section.

To start the case study

To display the first question in this case study, click the Next button. Use the buttons in the left pane to explore the content of the case study before you answer the questions. Clicking these buttons displays information such as business requirements, existing environment, and problem statements. If the case study has an All Information tab, note that the information displayed is identical to the information displayed on the subsequent tabs. When you are ready to answer a question, click the Question button to return to the question.Background

Best for You Organics Company started as a home-based business. The founders began making handmade soaps and bath products in their kitchen. As sales increased, the business established a production facility and distribution center that supplies three retail stores.

Soaps and bath products are manufactured in the production facility and are stocked in the warehouse for distribution to the retail stores. Employees at retail stores use mobile point of sale (MPOS) tablet devices to sell the products to customers.

The company structure is a single legal entity with two sites as shown in the diagram below:

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q13 085 Current environment

Best for You Organics plans to introduce a new product line of face creams. Each product in the new line uses the same base ingredients but includes a different extract (for example, lime, avocado, kiwi). The marketing department is preparing to introduce the new product line. Minimal inventory will be held in the warehouse.

The company uses a cloud-based deployment of Dynamics 365 Supply Chain Management to manage finances for all company operations and locations. The company does not use Bill of Materials (BOM) versioning.

The production and warehouse facility is set up with the following organizational hierarchy:

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q13 086 External customers include:

– Customer A: a walk-in store customer (business-to-consumer)

– Customer B: a customer with an existing account (business-to-business)External vendors include:

– Vendor A: a trucking company

– Vendor B: a raw materials supplierRequirements. General

The new product line must be set up in the system and readily available for sale when the company introduces the product line to the public at an upcoming trade show.

Requirements. Production

You must configure the system to produce the new products:

– Ensure that the warehouse stocks the minimum quantities of raw materials to produce the products.

– Use a single version per item.

– Implement FIFO inventory valuation methods.

– Track raw and finished goods using different General ledger accounts.

– Use a primary location to determine where to stock product in the warehouse.

– Configure alternate locations in the warehouse to hold overstock products and refill the primary location as-needed.Requirements. Shipments

You identify the following requirements related to shipping:

– Ship product to retail stores weekly.

– Stores require a packing slip to check in merchandise. Drivers require transport documentation and charge per mile to the stores.

– Shipments to Store1 must be scheduled for Monday, Wednesday, or Friday. Store1 will sometimes pick up their own deliveries when an order is small because they have their own van. Shipments to Store2 and Store3 must be scheduled for Tuesday or Thursday.

– You must transmit Advance Shipping Notifications (ASN’s) to the stores prior to deliveries.

– Set up the system configuration to allow for store transfers.

– Set up the system so that products may be shipped to the retail stores as bulk orders.

– Set up the transport providers to deliver products from the warehouse to the retails stores.Requirements. Reporting

Once the new products are available in stores, review 30 days of historical sales data from day-to-day transactions will determine the reorder quantities.

Set up reporting to allow the product line to be costed and tracked independent of other items.

Requirements. Pricing and inventory

You identify the following requirements related to pricing and inventory:

– Determine the quantity of the new products that can be produced and ready for sale within the first 90 days. Ensure that specialty packaging is on hand for retail sales. The packaging must be shipped directly to the stores from the vendor.

– Stores must not inventory the packaging materials. Stores must maintain a 30-day supply of specialty packaging materials. Stores must reorder packaging materials as needed.

– Retail store customers must pay full retail price. Resellers must receive a 10 percent discount off the list price.-

You need to complete the shipments.

What should you do?

- Confirm the load and generate packing slips and bills of lading.

- Confirm shipments, generate shipping documents, and send an ASN.

- Confirm shipments and generate pick/put work.

- Confirm the load, generate picking lists, and send an ASN.

-

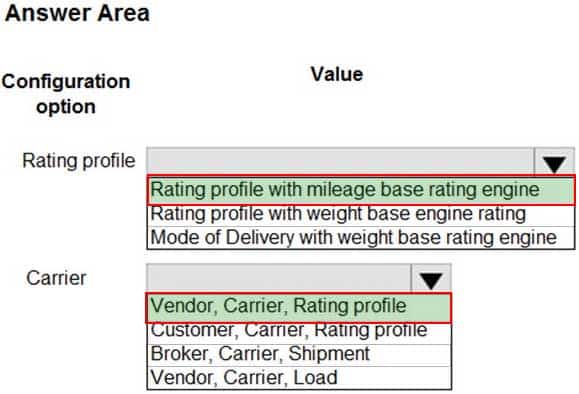

HOTSPOT

You need to consolidate orders and prepare to rate shop shipments.

How should you complete the setup? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q13 087 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q13 087 Answer -

HOTSPOT

You need to create new location directives.

Which values should you use? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q13 088 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q13 088 Answer -

HOTSPOT

Employee3 needs to schedule deliveries.

How should Employee3 plan for a carrier to deliver goods to Store2? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q13 089 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q13 089 Answer -

HOTSPOT

You need to configure transport providers for delivering products to the retail stores from Vendor1.

How should you complete the configuration? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q13 090 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q13 090 Answer

-

- This is a case study. Case studies are not timed separately. You can use as much exam time as you would like to complete each case. However, there may be additional case studies and sections on this exam. You must manage your time to ensure that you are able to complete all questions included on this exam in the time provided.

To answer the questions included in a case study, you will need to reference information that is provided in the case study. Case studies might contain exhibits and other resources that provide more information about the scenario that is described in the case study. Each question is independent of the other questions in this case study.

At the end of this case study, a review screen will appear. This screen allows you to review your answers and to make changes before you move to the next section of the exam. After you begin a new section, you cannot return to this section.

To start the case study

To display the first question in this case study, click the Next button. Use the buttons in the left pane to explore the content of the case study before you answer the questions. Clicking these buttons displays information such as business requirements, existing environment, and problem statements. If the case study has an All Information tab, note that the information displayed is identical to the information displayed on the subsequent tabs. When you are ready to answer a question, click the Question button to return to the question.Background

Adventure Works Cycles builds stock and custom mountain bikes and is headquartered in San Diego. It has the following assembly and warehouse locations:

– Denver, Colorado, United States

– San Diego, California, United States

– Budapest, HungaryMost manufacturing is outsourced, with each facility only assembling the bikes. Parts are stocked at all facilities and may be transferred between warehouses or legal entities. All of the parts are at standard cost.

Current environment. Organizational structure

The following diagram shows the structure of Adventure Works Cycles.

– Each of the physical locations in the United States (US) is a warehouse.

– Hungary assembles and distributes products to the rest of the European Union (EU).

– The EU legal entity is expected to add additional warehouse locations.

– All legal entities roll up to a financial consolidation company.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q14 091 Current environment. Purchasing

– Higher quality tires that are used in new orders have become popular. Due to the volume of orders, the company wants to negotiate pricing with Vendor C. The vendor agrees to a discounted price for 500 tires purchased within the next six months. Once the 500 tires have been purchased, the discount will be re-evaluated based on demand.

– Once a purchase is approved, for audit purposes it cannot be changed.

– Whenever possible, parts are purchased from vendors also within the EU. A purchase order was placed for a bike seat manufacturer in Italy.

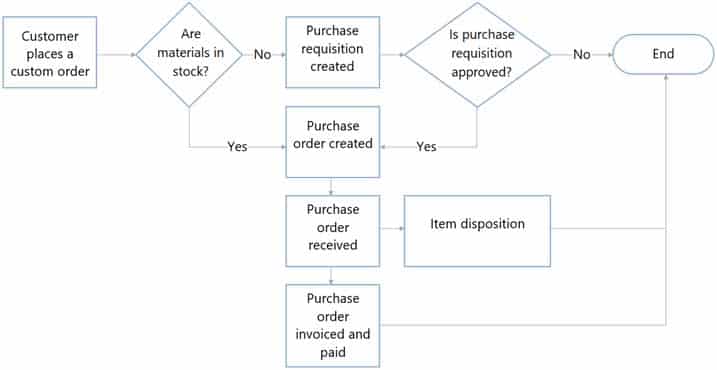

– Parts for custom orders may not always be kept in stock and will need to be procured.Current environment. Purchase requisitions

The following flow chart depicts the purchase requisition process:

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q14 092 Requirements. Purchasing

– Items for purchase requisitions are governed by each country. Each of the country-specific products will be grouped together for selection.

– Purchase orders must follow the requisition process.

– All existing purchase orders for brakes must account for the change to Vendor B.Requirements. Inventory

– Standard costs are based on purchase fluctuations within a single month.

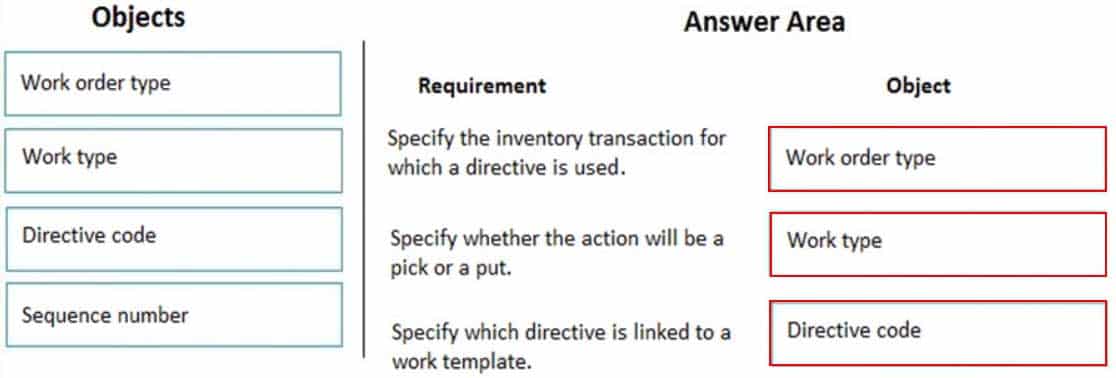

– Tires use floating zones due to limited warehouse space.Requirements. Operations

Due to recent brake failures, Adventure Works Cycles plans to purchase brakes from Vendor B instead of Vendor A. Although the brakes from Vendor B will continue to use the same item number as the brakes from Vendor A, the price is slightly higher from Vendor B. Adventure Works Cycles will pay list price from Vendor B. The order for Vendor B needs approval and the usual approver for purchase requisitions is on vacation.

All brakes from Vendor A that are in stock must be tested. The process for brake testing must be implemented for all inbound orders. Quality orders must be automatically created upon receipt of the first shipment against a purchase order only. Inventory stocking locations must be consolidated after the brakes are tested.

User C needs to consolidate brake inventory after it has been cleared for sale.

Ordering of the new brakes order will incur an additional cost because it is a rush order.

Requirements. Custom orders

– Custom orders are placed for items that do not exist in the item master.

– Hungary does not process custom orders.

– The United States does process custom paint orders. Most custom paint colors are special order and require purchase requisitions.

– Quotes must be obtained from a minimum of two suppliers per company policy and compared for the shipping, costs, and other variables. Quotes will not be selected based on lowest price only.Issues

– A special order for 2.6 high-end tires is received. This item is no longer in stock from the current vendor.

– Goods have been received in stock, but the matching invoice has not yet been received at the time of month close.

– User A needs to set up pricing for the items purchased from Vendor C and ensure that accounting validates the receipt and invoice against the agreement.

– User B needs to send out a request for quotation (RFQ) for custom paint. The vendor will be selected based on pricing, volume discounts, and lead time.-

HOTSPOT

You need to define where the tires should be put away in the warehouse.

How should you set up the location directives? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q14 093 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q14 093 Answer

-

-

You are the planner for a distribution company.

You observe an increase in planned orders for item C0001. You must track the source for these planned orders and break them out based on their demand. You are not concerned with safety stock maximums for this item.

You need to ensure that the master planning batch job will create a unique planned purchase order for every new demand requirement for C0001.

Which coverage code should you use?

- Manual

- Period

- Min/Max

- Requirement

-

SIMULATION

You are a functional consultant for a company named Contoso Entertainment System USA (USMF).

You need to regenerate a master plan named DynPlan for item number D0023.

To complete this task, sign in to Dynamics 365 portal.

- See explanation below.

Explanation:You specify the planning method in the Master planning run dialog box. To open this dialog box, go to Master planning > Master planning > Run > Master planning, or select Run in the Master planning workspace.

Regeneration

The regeneration planning method deletes existing planned orders, unless they are firmed. It generates new planned orders, based on all the requirements. Regeneration is the only planning method that is available for static plans.

– Changes in supply are considered. These changes include changes in the forecast.

– This method respects the Period coverage code.

– This method supports product substitution functionality (PI).Select DynPlan in the Master Plan field.

Select Regeneration in the Planning Method field.

Enter D0023 in the Item Number field. -

DRAG DROP

A manufacturing company is setting up a new warehouse.

The warehouse must store a product that is currently stored in another warehouse.

You need to create new item coverage for the warehouse.

Which four actions should you perform in sequence? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q17 094 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q17 094 Answer -

A company operates a chain of retail coffee shops and a distribution center. Each coffee shop and the distribution center are distinct warehouses.

Cups and lids are replenished from a single distribution center.

You need to configure store replenishment for coffee cup lids.

Which three actions should you perform? Each correct answer presents part of the solution.

NOTE: Each correct selection is worth one point.

- Set the coverage plan by dimension for warehouse on the Storage dimension group.

- Set the minimum item coverage to the safety stock quantity. Set the maximum to the maximum quantity of stock to reorder above the safety stock quantity.

- Set the minimum item coverage to the safety stock quantity. Set the maximum item coverage to 0.

- Create a coverage group assignment for the item.

- Set the minimum item coverage to 0. Set the maximum item coverage to the number of lids to keep on hand.

-

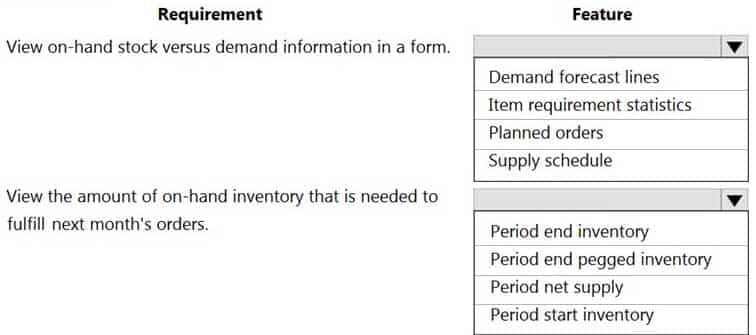

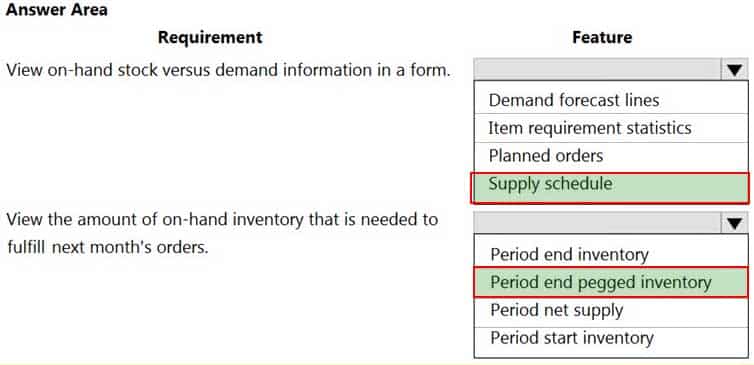

HOTSPOT

A company uses Dynamics 365 Supply Chain Management to sell consumer electronics to retailers across North America.

An inventory manager needs to view purchase orders by different periods of time for all warehouses.

If there are insufficient orders for expected demand, the manager must create new purchase or transfer orders to meet the demand versus the current on-hand inventory that is already allocated for future demand.

The company also needs to keep a surplus of 5 percent of inventory for unexpected demand.

You need to identify a solution to meet these requirements.

Which feature should you use for each requirement? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q19 095 Question

MB-330 Microsoft Dynamics 365 Supply Chain Management Part 08 Q19 095 Answer -

A company uses planning optimization in Dynamics 365 Supply Chain Management. Automatic firming is enabled.

Some of the planned purchase orders are not being firmed as expected. The inventory planners therefore need to manually process planned purchase orders.

You need to include the planned purchase orders in automatic firming.

What are two possible configurations you can use? Each correct answer presents a complete solution.

NOTE: Each correct selection is worth one point.

- Lead Time

- Automatic firming time fence (days)

- Requirements Date

- Freeze time fence on master plan